Understanding Intelligent Chemical Engineering Solutions and Their Role in Modern Plants

Defining Intelligent Chemical Engineering Solution in the Context of Chemical Manufacturing

Smart chemical engineering approaches bring together artificial intelligence (AI), machine learning (ML), and Internet of Things (IoT) sensors to really boost what's possible in chemical manufacturing these days. The systems look at both current and past data streams which helps factories run better, get more accurate results from their processes, and cut down on wasted materials. Traditional approaches just can't match this kind of flexibility since smart systems actually adjust themselves when things change without needing constant human oversight. Take a recent study from McKinsey in 2023 for instance. They looked at plants that had implemented these intelligent technologies and found something pretty impressive: those facilities saw around 28 percent improvement in how efficiently they used catalysts and controlled reaction temperatures compared to old fashioned manual methods. That kind of difference makes a big impact on bottom lines across the industry.

Integration of Artificial Intelligence in Chemical Manufacturing for Operational Oversight

Artificial intelligence is making a real difference in how factories monitor their operations, especially when it comes to spotting potential equipment problems before they happen and automatically triggering safety measures. These smart systems can crunch massive amounts of information every second coming from those complicated control panels throughout manufacturing plants. They're pretty good at catching issues nobody would normally notice, like when materials aren't mixed properly or when machines are guzzling way too much power. Some recent studies show that facilities using AI for process control have seen around a 15-20% drop in unexpected shutdowns across various industries. This kind of improvement means fewer production hiccups and happier plant managers who no longer spend their days chasing down mysterious breakdowns.

Transition From Traditional to Data-Driven Plant Management Systems

Manufacturers across various industries are moving away from old school systems toward modern data platforms that link lab information management (LIMS) with enterprise resource planning (ERP) solutions. According to research published by ARC Advisory in 2023, facilities that made this switch saw around 25% better consistency between batches and got their regulatory reports done about 14% quicker. What makes these combined systems so valuable is the big picture view they offer. Engineers can actually see how what's happening on the production floor matches up against current inventory stocks and what customers are asking for in the marketplace right now. This kind of real time alignment just wasn't possible with separate systems before.

Real-Time Process Optimization Using AI and Machine Learning

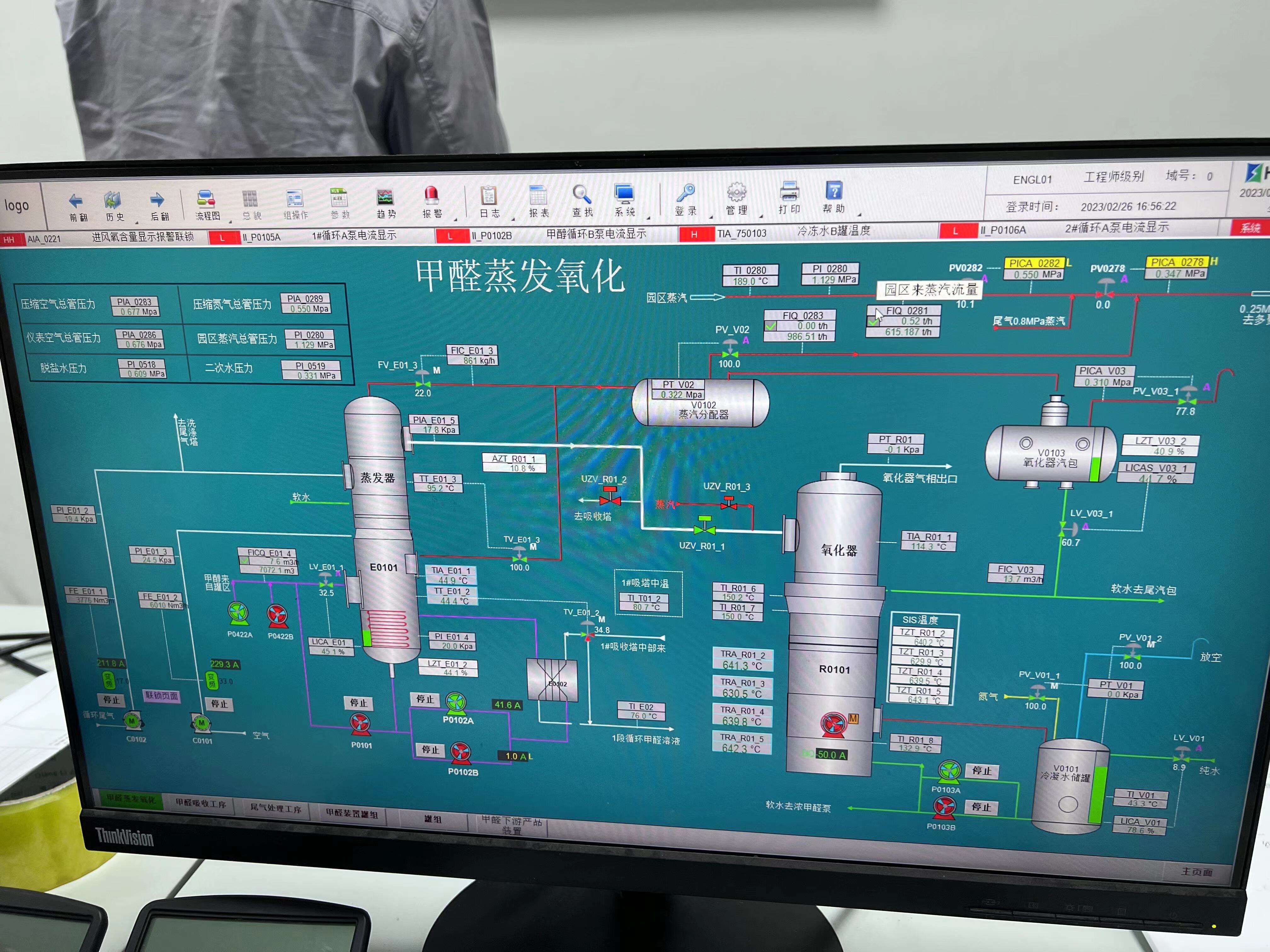

Real-time data integration for operational decision-making in chemical plants

Smart chemical engineering systems now rely on IoT sensors combined with distributed control systems (DCS) to handle around 15 thousand data points every single second throughout manufacturing facilities. With this constant stream of information, artificial intelligence can tweak reactor temps, manage pressure settings, and fine tune feedstock proportions all within about half a millisecond. That's roughly 35 times quicker than what any human operator could possibly achieve. The result? Much better control over complicated industrial processes where timing matters a lot. Plants using these technologies report fewer errors and improved efficiency when handling those tricky chemical reactions that require such fast responses.

Applications of artificial intelligence and machine learning in dynamic process control

Machine learning algorithms autonomously manage variables such as catalyst decay and exothermic reaction thresholds. A 2023 industry study showed these systems maintain product quality within 0.3% of specifications during raw material fluctuations, outperforming traditional PID controllers by a 19:1 margin in stability benchmarks.

Process optimization using AI to enhance yield and reduce waste

AI-driven process models identify energy-intensive stages in batch production and recommend predictive adjustments, leading to 12–18% yield improvements. One polymer manufacturer reduced ethylene waste by 22% by implementing reinforcement learning models that optimized monomer conversion rates.

Case study: AI-driven reactor optimization reducing batch variability by 32%

A specialty chemicals plant deployed deep learning across 14 continuous stirred-tank reactors, reducing batch-to-batch viscosity variation from ±8% to ±2.7% within six months. The $2.7M investment cut annual quality control costs by $410,000 and achieved 99.4% first-pass yield compliance, according to the 2024 Process Engineering Report.

Predictive Maintenance and Anomaly Detection in Chemical Processing Equipment

Predictive Maintenance in Chemical Plants Using Machine Learning Models

Chemical plants use machine learning models to analyze sensor data, vibration patterns, and thermal metrics from critical equipment like reactors and pumps. By detecting deviations from normal performance, these systems predict component wear 12–18 days in advance (Ponemon 2023), helping avoid unplanned downtime, which averages $740,000 per incident.

Minimizing Downtime Through Early Failure Detection and Anomaly Alerts

Anomaly detection systems powered by artificial intelligence look at risks according to how important different pieces of equipment are to operations. When it comes to spotting problems early, vibration analysis helps catch bearing wear in agitators before it gets bad. Thermal imaging can pick up when distillation columns start getting too hot, while oil condition sensors keep track of lubricant quality in compressors over time. Looking at a mining operation from 2025 gives us some real world numbers here. They saw their equipment failure rate drop around 40% once they started monitoring things in real time. For chemical plants that have adopted similar approaches, maintenance downtime tends to shrink somewhere between 25 and 30 percent compared to traditional methods. This means less production loss and fewer unexpected breakdowns disrupting workflow.

Balancing Automation and Human Expertise in Predictive Systems

AI handles all that sensor data coming in from everywhere, but humans still need to check what's going on and put things into perspective. When machine learning spits out those failure probability numbers, experienced engineers step in. They tweak the system settings when seasons change, since winter conditions aren't the same as summer ones. Most importantly, these experts take charge whenever an automatic suggestion clashes with established safety rules, which happens around 8 out of 10 times according to industry reports. The combination works pretty well overall, keeping predictions accurate about 92% of the time while cutting down on those annoying false alarms that nobody wants to deal with.

Energy Efficiency and Cost Savings Through Intelligent Process Control

Energy Management and Efficiency Optimization via Intelligent Chemical Engineering Solution

Smart chemical engineering approaches can really cut down on energy waste through adjustments to heat exchange processes, pump settings, and reactor parameters. These advanced systems look at all sorts of plant data layers to spot where things aren't running efficiently like when too much steam is being used or heat isn't properly recovered, then they tweak the equipment automatically. Take AI controlled systems for example, they change valve positions and manage how heat moves through exchangers according to what the system predicts it will need next, which means no more mistakes that come from people trying to adjust things manually.

Use of AI and Data-Driven Models in Process Control for Energy Conservation

AI models balance energy conservation with production goals by combining live sensor data with historical trends to forecast equipment stress and optimize performance. One application involves modulating compressed air systems to match real-time pneumatic tool usage, avoiding constant operation and reducing energy waste.

Data Point: AI Implementation Reduced Energy Consumption by 18% in a European Petrochemical Facility

A 2023 deployment at a European petrochemical plant achieved an 18% annual reduction in energy consumption by optimizing reactor cooling cycles and distillation column pressures. This cut CO² emissions by 11,500 metric tons—equivalent to removing 2,500 cars from the road—while maintaining 99.7% product consistency.

Digital Twin and Cyber-Physical Systems for Advanced Plant Simulation

Digital twin technology in industrial applications for virtual process replication

Digital twin tech builds virtual copies of actual chemical plants that can mimic how equipment works, track chemical reactions happening inside, and show what's going on throughout the whole facility as it happens. A recent study from ScienceDirect in 2024 looked at this closely and found three main parts make these digital twins work: sensors connected to the internet that feed real time information, mathematical models based on physical laws to simulate what would happen, plus some smart algorithms that guess how systems might react under different conditions. What makes this approach so valuable is that plant engineers can try out new processes, check what happens during emergency situations, tweak settings for better performance all while the real plant keeps running normally. No need to shut anything down just to run tests anymore.

Cyber-physical systems for real-time plant simulation and control

When cyber physical systems bring together digital twin data alongside PLCs and distributed control systems, they create those closed loop feedback mechanisms needed for true autonomous operation. These setups cut down on how much hands on work operators need to do for everyday tasks, all while keeping detailed records that meet ISO 9001 standards for quality management. What really stands out though is the speed factor - most modern implementations manage to stay within half a second latency window. This kind of responsiveness lets manufacturers make proactive changes when there are variations in incoming materials or shifts in available power resources throughout production cycles.

Virtual commissioning and testing of industrial equipment through AI-powered modeling

Virtual commissioning powered by artificial intelligence speeds up deployment because it allows for testing control logic and safety interlocks without any real-world risks. It also automatically finds conflicts between mechanical parts and electrical components, plus compares system performance with past data. For engineers, this means they can run simulations showing how equipment wears down after thousands of cycles. These tests help them fine tune when maintenance should happen, which cuts down on unexpected breakdowns. Some studies suggest this approach might cut unplanned downtime by around 25-30%, way better than old fashioned trial and error methods that often lead to costly surprises.

Case study: Digital twin reduces startup time by 40% in a specialty chemicals plant

One European company that makes specialty chemicals put together a digital twin specifically for their reactor to work out the best way to activate catalysts. They ran virtual tests on more than 1,200 different combinations of temperature and pressure settings. The result? The plant got everything running properly about two weeks quicker than it used to take before. According to some findings from Siemens back in 2024, this whole process cut down on wasted energy during setup by around 31 percent without messing with the product quality much at all - they kept it pretty consistent with only about plus or minus 0.8% variation.

FAQs on Intelligent Chemical Engineering Solutions

What is a smart chemical engineering solution?

A smart chemical engineering solution integrates AI, ML, and IoT sensors to enhance chemical manufacturing capabilities, streamline operations, and reduce waste.

How do AI systems improve operational oversight in chemical plants?

AI systems monitor massive data streams in real-time to identify and address potential equipment issues, improving plant safety and reducing unexpected shutdowns.

Can intelligent chemical engineering solutions reduce energy consumption?

Yes, AI-driven systems optimize processes to conserve energy, significantly reducing energy waste and overall consumption in chemical manufacturing facilities.

Table of Contents

- Understanding Intelligent Chemical Engineering Solutions and Their Role in Modern Plants

-

Real-Time Process Optimization Using AI and Machine Learning

- Real-time data integration for operational decision-making in chemical plants

- Applications of artificial intelligence and machine learning in dynamic process control

- Process optimization using AI to enhance yield and reduce waste

- Case study: AI-driven reactor optimization reducing batch variability by 32%

- Predictive Maintenance and Anomaly Detection in Chemical Processing Equipment

- Energy Efficiency and Cost Savings Through Intelligent Process Control

-

Digital Twin and Cyber-Physical Systems for Advanced Plant Simulation

- Digital twin technology in industrial applications for virtual process replication

- Cyber-physical systems for real-time plant simulation and control

- Virtual commissioning and testing of industrial equipment through AI-powered modeling

- Case study: Digital twin reduces startup time by 40% in a specialty chemicals plant

- FAQs on Intelligent Chemical Engineering Solutions