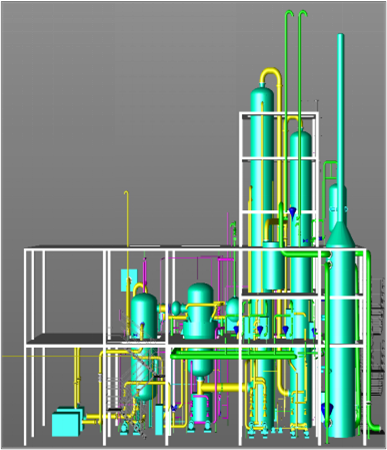

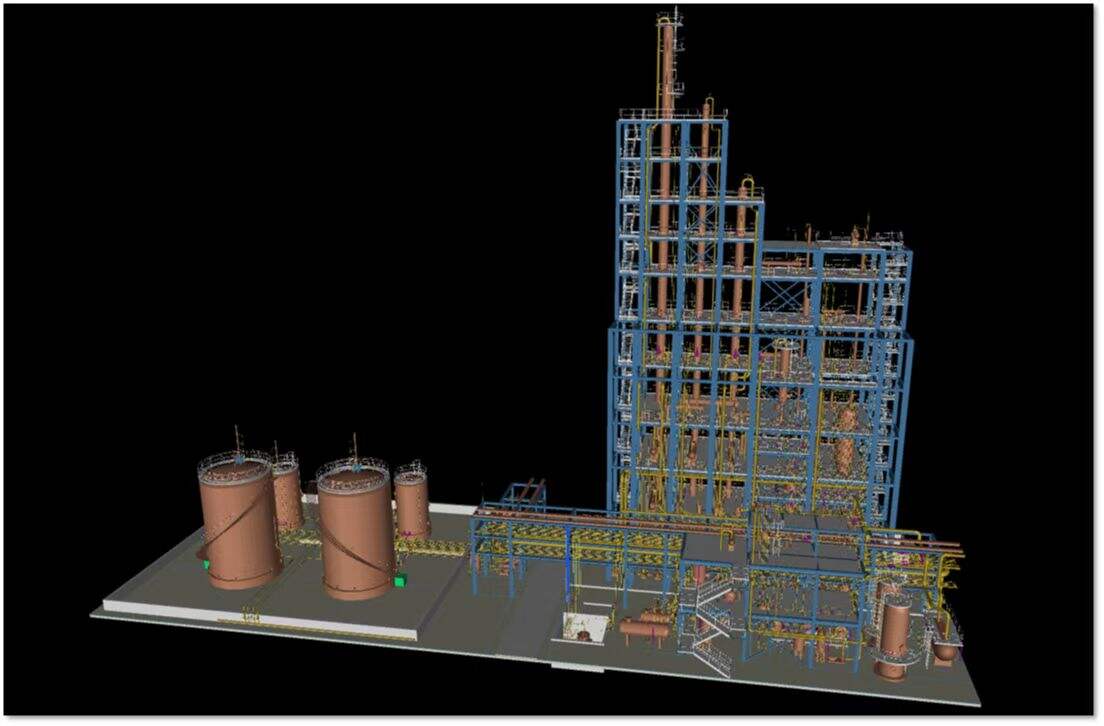

At our Acetic Acid Process Plant, both the design and the process are the center of attention for engineers and technologists. It is time to promote new ideas that focus on higher efficiency, sustainability and promote best practices enabling us to stand out from the crowd. We provide support through every stage of the production commencing from the first drawing to the final commissioning covering all aspects necessary for safe and efficient operation of a process plant. Chemical Process Engineering is never stagnant at this company and our focus on quality speaks for our projects.