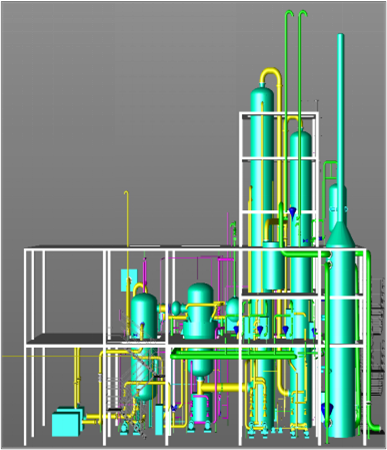

The company’s chemical process design services are rooted in technical excellence and project execution expertise. Starting with process synthesis, multiple route options are evaluated using criteria like atom economy, E-factor (environmental factor), and process complexity. For example, a pharmaceutical API production process was designed using a continuous flow reactor instead of batch, improving yield from 68% to 89% and reducing solvent usage by 70%. Detailed design includes equipment specification (reactors: jacketed with heating/cooling media, heat exchangers: U-tube with removable bundle), piping and instrumentation diagrams (P&IDs), and control philosophy development. Design reviews are conducted at key milestones (conceptual, preliminary, detailed) to ensure alignment with client requirements, including HSE (health, safety, environment) considerations. The company also provides process design packages (PDPs) suitable for construction, including material take-offs, equipment datasheets, and plot plans.