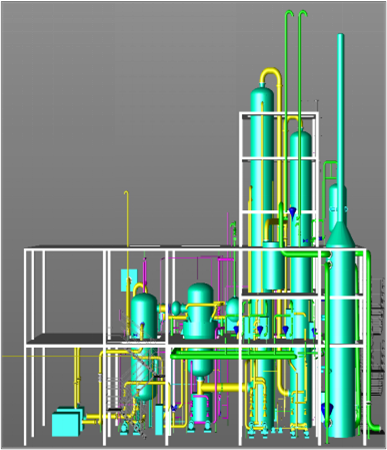

The integration of chemical processes design and simulation is an engineering practice that takes into account all aspects of chemical engineering combining theoretical and real world applications. We have high level chemical engineering programs, simulations allow us to model how different reactions and processes behave with respect to time, and these quantitative data can then be used to provide building blocks for optimization techniques. This not only improves the overall effectiveness of the current practices but enables the creation of new systems and processes that comply with given standards. Sourcing for sustainable solutions and safety guidance practices also control harm while the desired quality and quantity is attained.