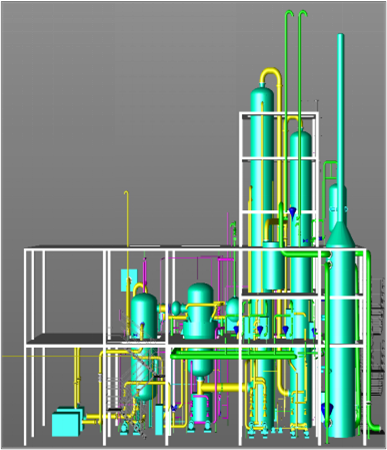

The company’s chemical engineering process design services combine technical depth with industry best practices, delivering solutions that balance performance, safety, and economics. Design teams are proficient in all aspects of process engineering, from unit operation design (reactors, separators, heat exchangers) to full-plant integration. For reactor design, criteria such as residence time (0.1 - 300 minutes), mixing intensity (Reynolds number > 10,000 for turbulent flow), and heat transfer coefficient (100 - 10,000 W/m²K) are carefully optimized. In mass transfer operations, such as absorption columns, design parameters like liquid-gas ratio (1 - 5 L/m³), packing height (5 - 20 m), and pressure drop (10 - 100 Pa/m) are tailored to process requirements. The company also offers specialized process design for emerging technologies, such as carbon capture and storage (CCS), with amine-based absorption systems designed to achieve CO₂ capture rates > 90%.