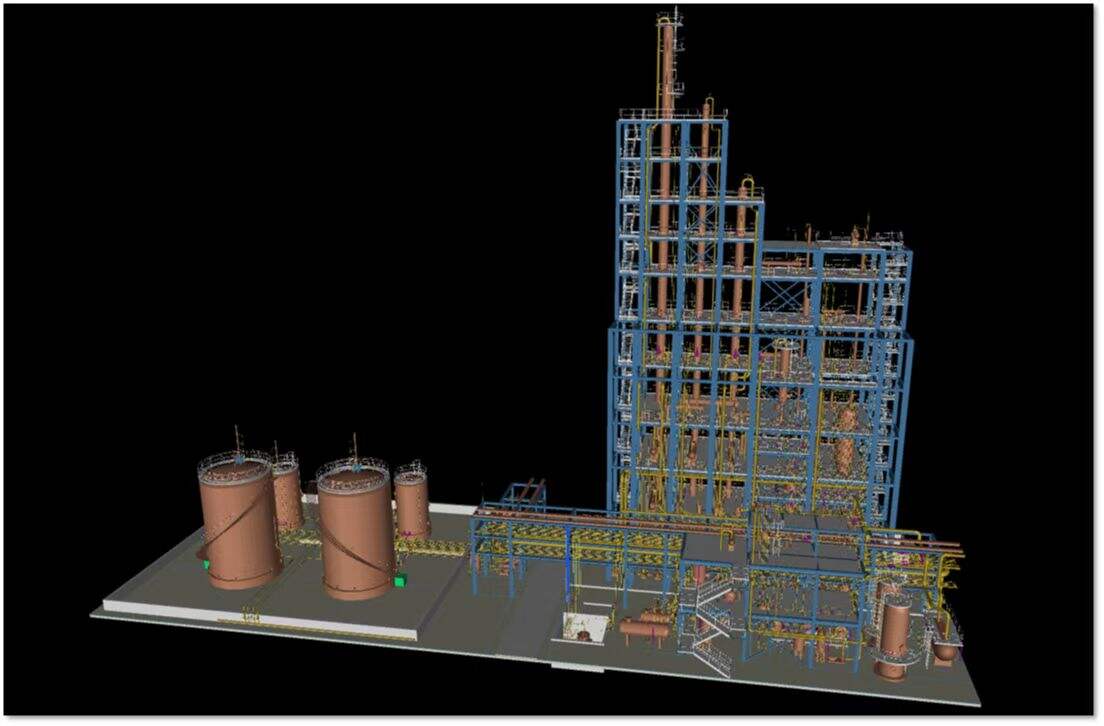

The company offers comprehensive chemical plant design services, integrating process, civil, electrical, and control disciplines for turnkey solutions. Plant layouts are optimized using computer-aided design (CAD) tools (AutoCAD Plant 3D), with considerations for process flow (from raw material intake to product dispatch), safety distances (compliant with API 752), and maintenance accessibility (crane runways, equipment lifting points). Civil engineering designs include foundation specifications (deep piles for heavy equipment), drainage systems (separate stormwater and process wastewater), and fire protection infrastructure (sprinkler systems, fire hydrants). Electrical design covers medium-voltage switchgear (10 kV), motor control centers (MCCs), and lighting systems (explosion-proof fixtures for hazardous areas). Smart plant features, such as IoT-enabled equipment monitoring (temperature, vibration sensors), are incorporated to enable predictive maintenance, reducing unplanned downtime by up to 40%.