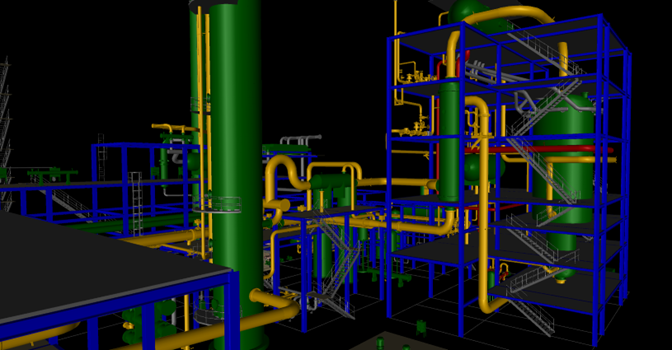

Sanli Tech possesses the capability to provide a complete preliminary chemical engineering plant design petal starting from feasibility studies through to mechanical erection drawings and diagrams. The operational methodology is that the Nelson Stud Version 7 converts all input data into desired designs anticipated in accordance with client requirements. Outlook with time examines existing innovative company focused design and optimization. Availability of high limits enhances the quality of customer service hence high satisfaction and support presence in the area of chemical engineering.