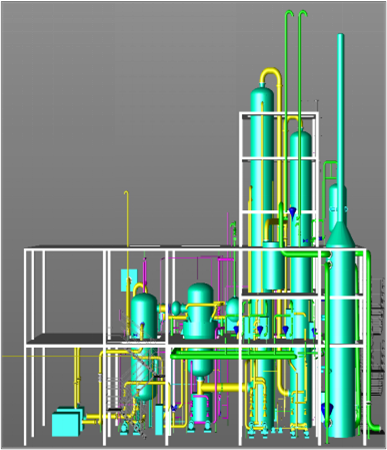

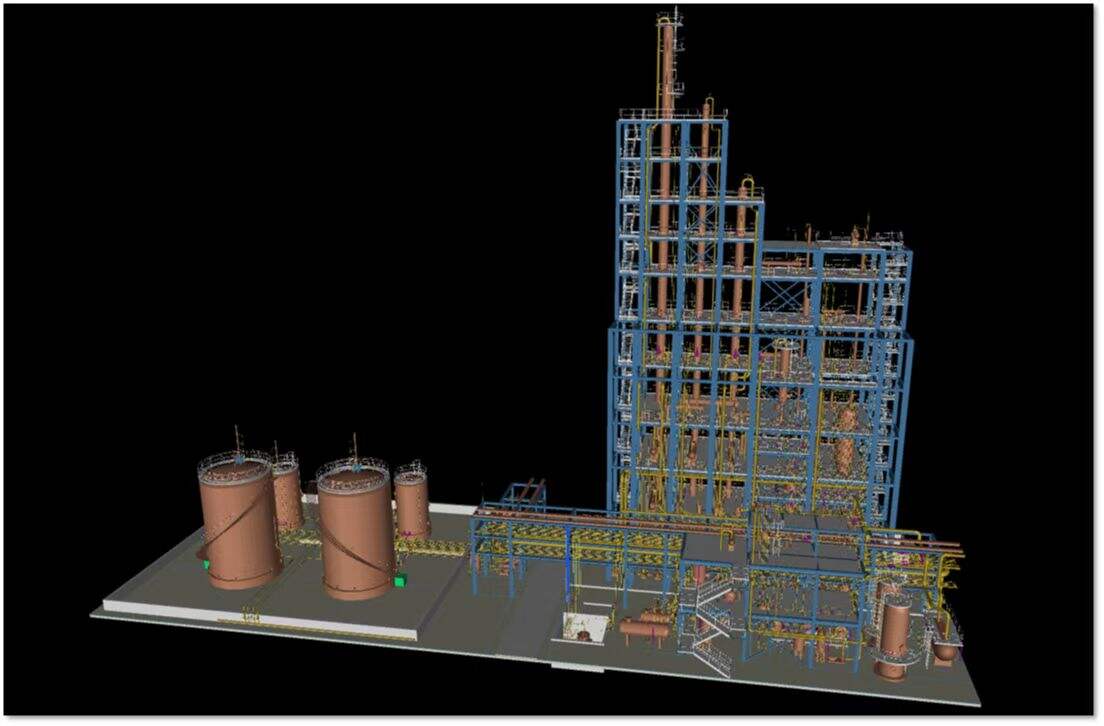

The company’s chemical engineering design services encompass the entire project lifecycle, from feasibility studies to post-commissioning support. Conceptual design involves process route selection and mass/energy balance development, with economic screening using metrics like payback period (< 3 years) and return on investment (ROI > 15%). Preliminary design includes equipment sizing, PFD (process flow diagram) development, and plot plan layout, while detailed design covers P&ID creation, equipment specifications, and construction drawings. Engineering teams are experienced in designing for various industries, including petrochemicals, pharmaceuticals, fine chemicals, and renewables. Notable projects include a 100 kt/year bioethanol plant using enzymatic hydrolysis of lignocellulosic biomass and a 50 kt/year carbon black plant with integrated flue gas desulfurization. The company also offers digital engineering services, including 3D plant modeling (using Bentley PlantWise) and construction sequencing simulations to optimize project schedules.