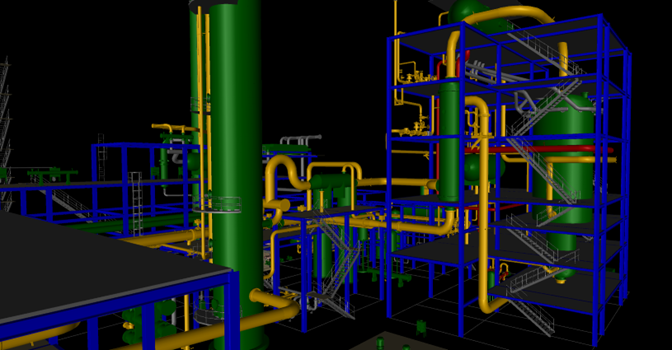

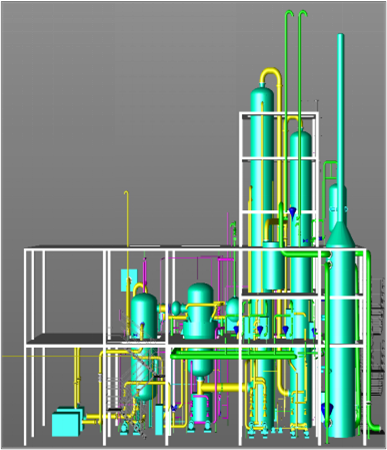

At Sanli Tech, the concentration is on the designing of chemical process plants, particularly aimed at providing timely, cost effective and innovative solutions satisfying the requirements of customers. It is our approach that incorporates the most advanced processes of chemical engineering that every plant is built to perform as designed and in an environmentally sound manner. Being equipped with the vast knowledge and experience in this industry together with our R and D capacity, Sanli Tech assists clients in all aspects of chemical processing from process design to the transfer of technology.