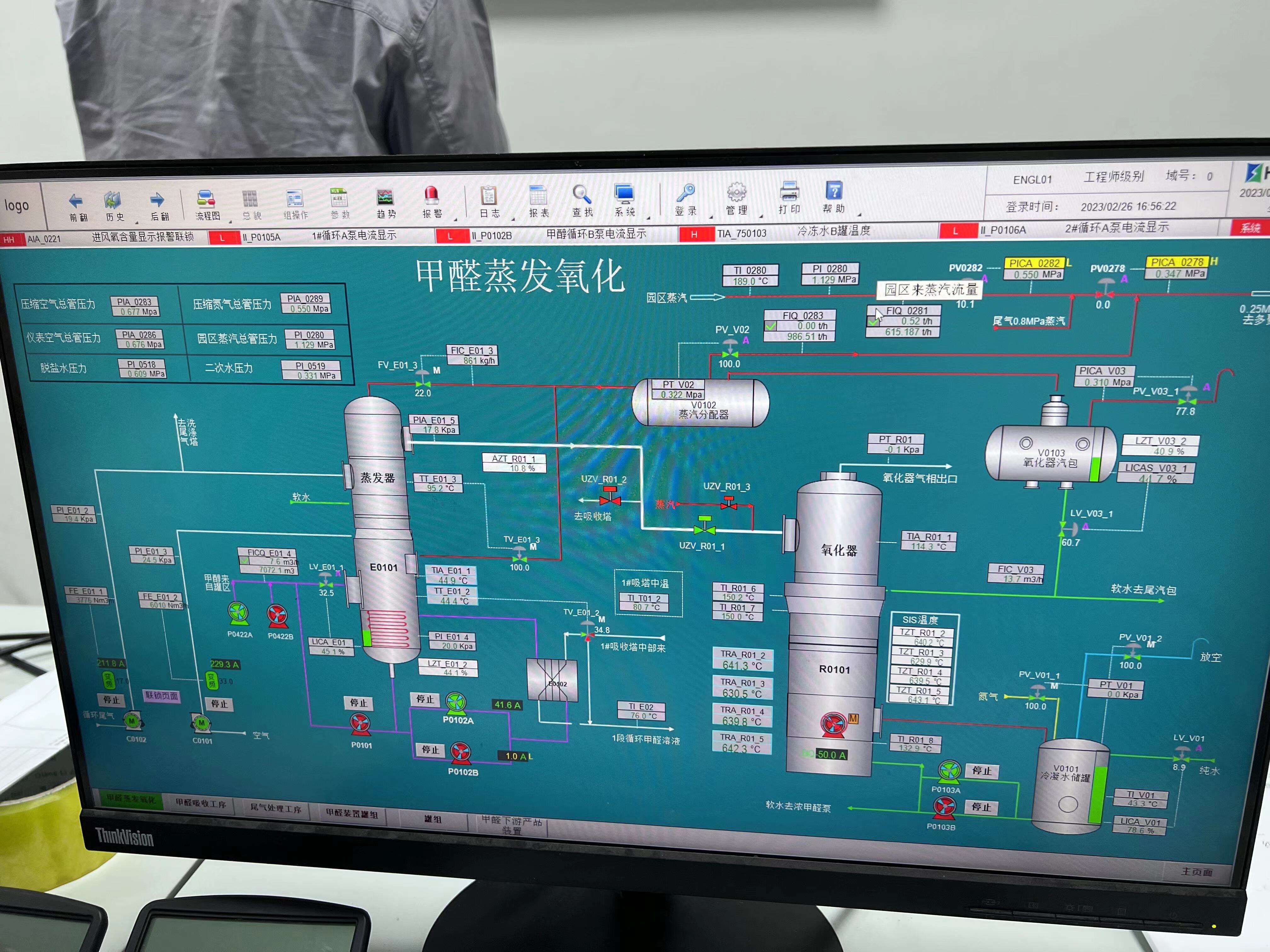

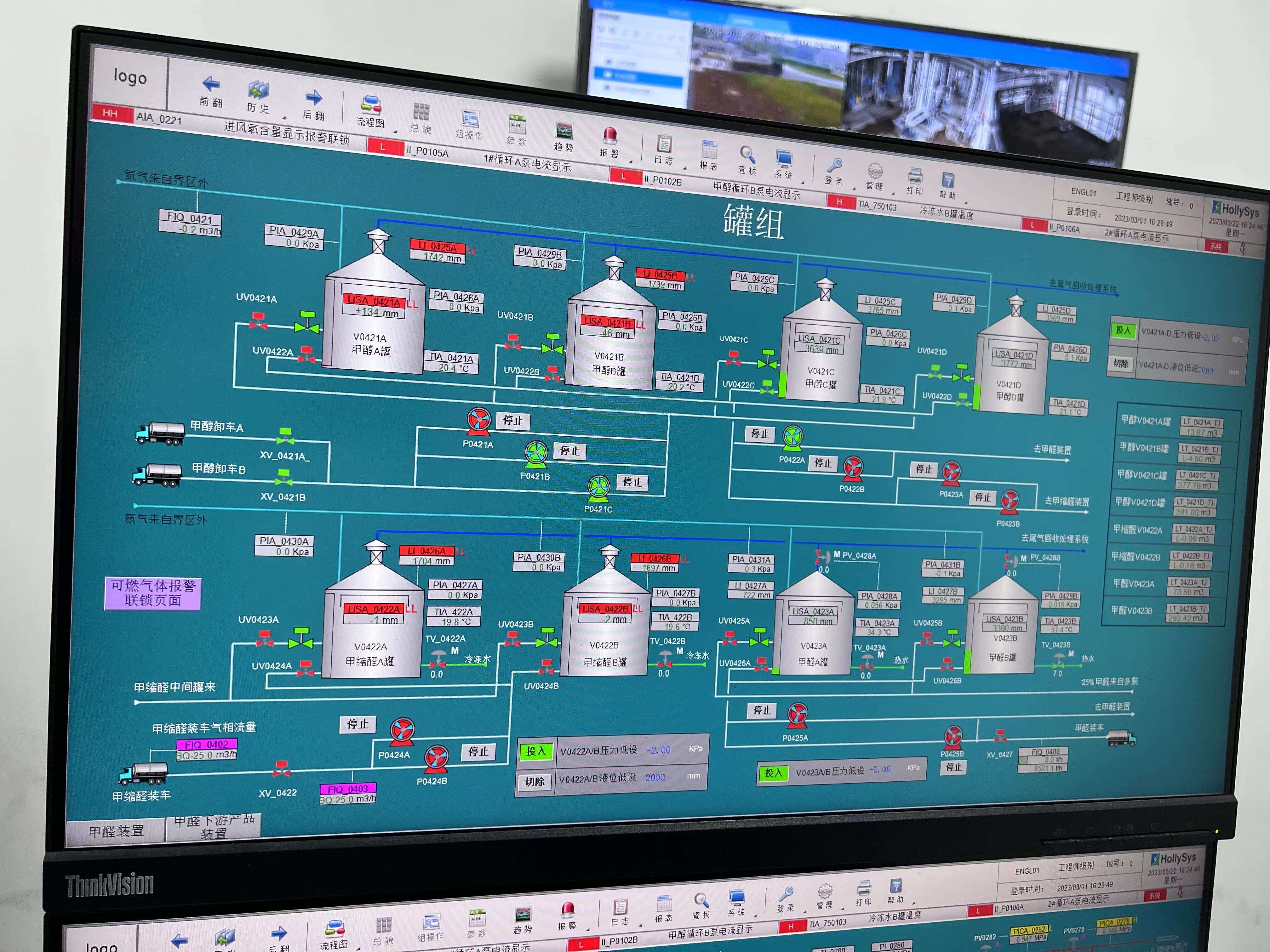

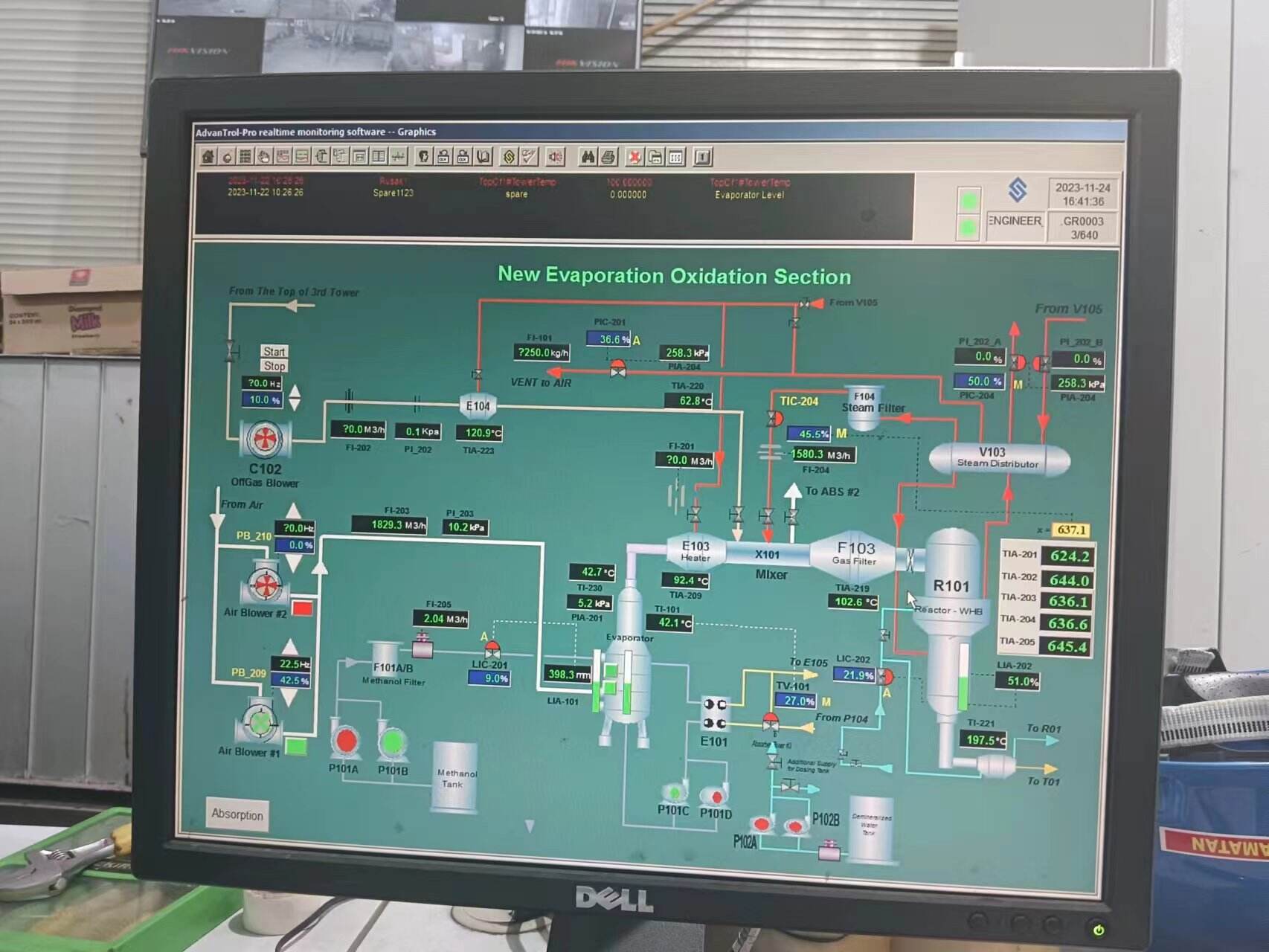

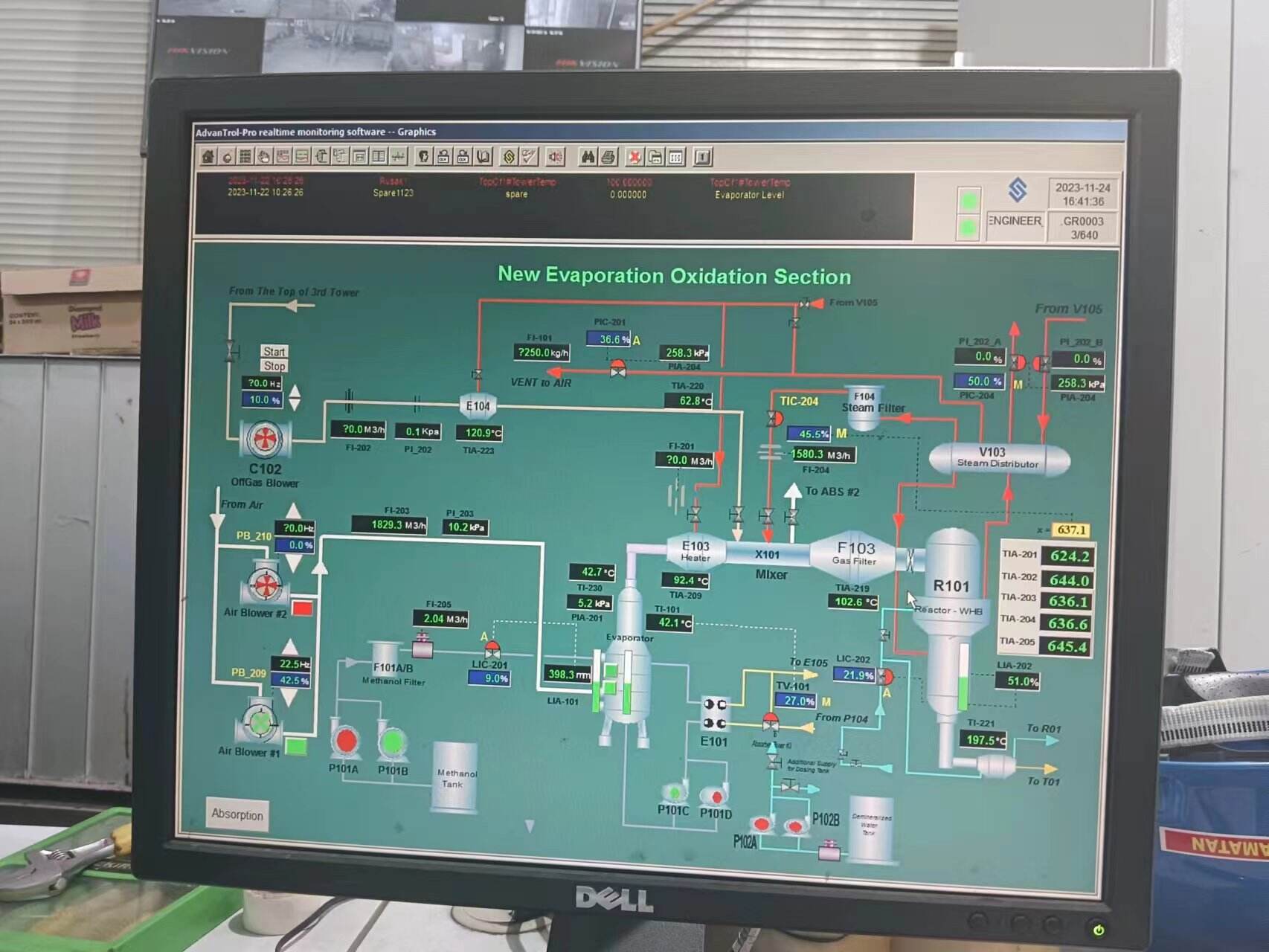

Sanli Tech focuses on the intelligent design of chemical engineering because optimal solutions can tackle problems of productivity and safety while carrying out chemical processes. We have extensive experience in the designing and commissioning of several types of systems which are customized to each customer’s requirements. Using modern technologies and innovative engineering solutions I assist businesses in streamlining business processes, reducing production and operational waste, and minimizing negative impacts on the environment. Our quality and sustainability factors make us an exceptional entity which has positioned itself in the echelon of the global chemical engineering industry.