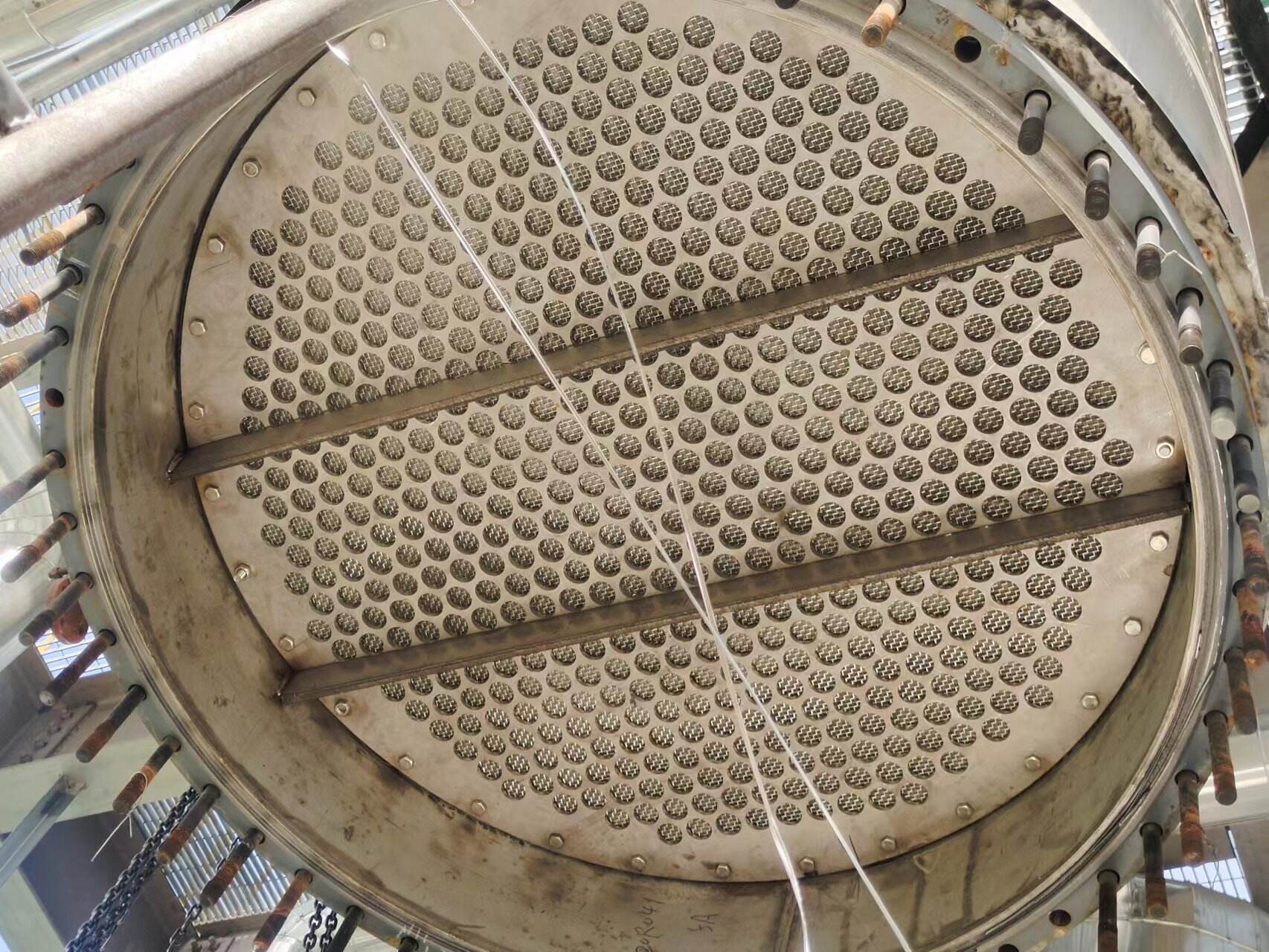

The company offers turnkey solutions for methanol production plants, integrating process design, equipment supply, and technical services. Plant designs follow a modular approach for fast construction, with prefabricated skids for synthesis gas preparation, methanol synthesis, and distillation. Key equipment includes reformers (fired or autothermal), methanol synthesis reactors (multi-tubular or liquid-phase), and distillation columns (with high-efficiency trays or packing). Instrumentation and control systems are designed for optimal plant operation, featuring advanced process control (APC) for reactor temperature and pressure management, and safety instrumented systems (SIS) for critical safety functions (SIL 2/3). Plant commissioning services include pre-commissioning (purging, hydrotesting), cold commissioning (instrument loop checks), and hot commissioning (feedstock introduction), with operator training provided throughout. The company also offers long-term plant maintenance contracts, including routine inspections, catalyst replacement, and equipment refurbishment.