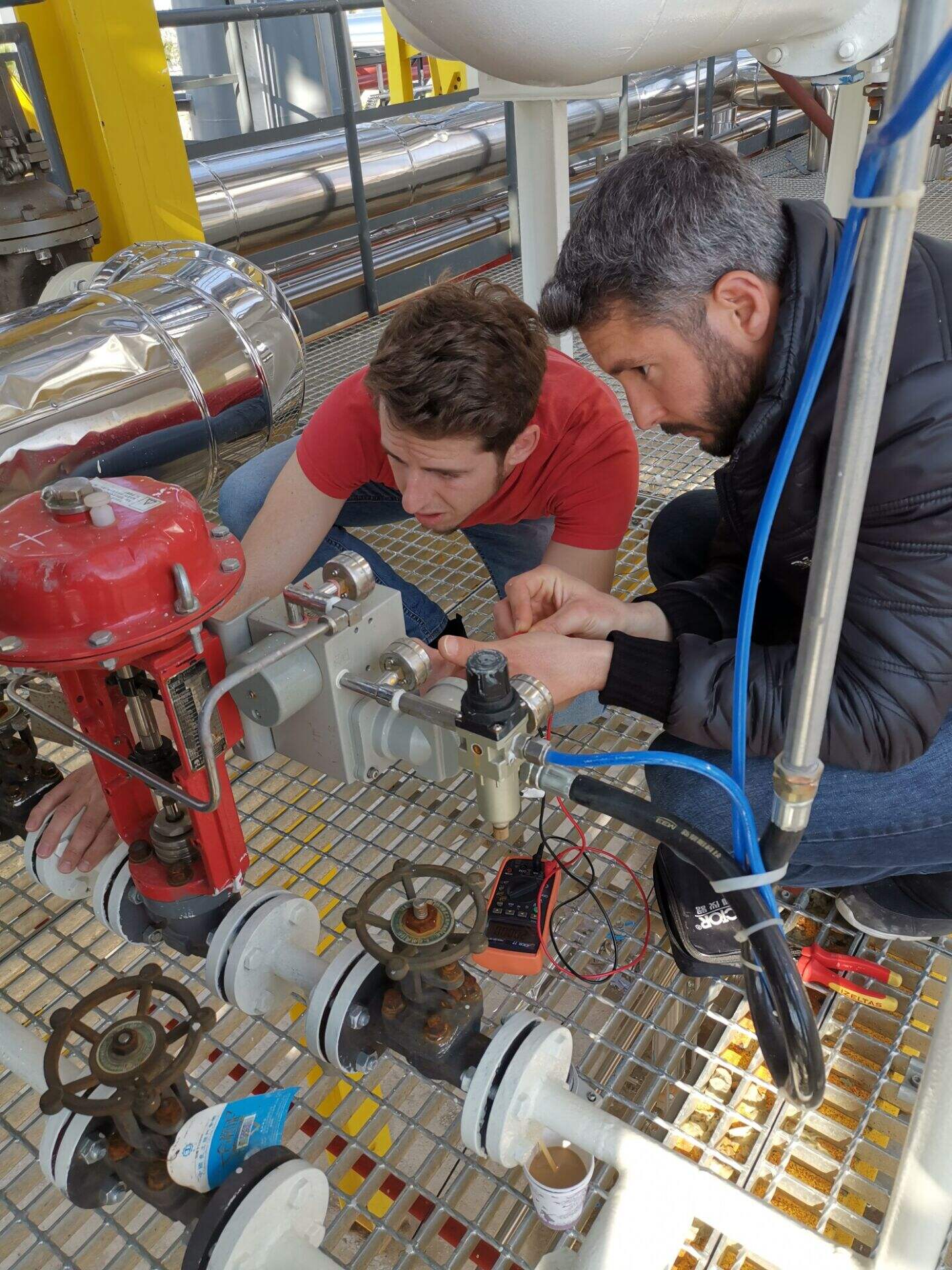

Sanli Tech offers onsite support for chemical plant operation with an aim and focus to improve the process and safety levels to achieve the desired results. Our consultants help our clients in optimizing their operations leading to a reduction in cost and enhancement of productivity. These teams also assist the client in identifying areas that require improvements and offer solutions that are targeted to the needs. Such planning ensures that the chemical plants are able to run at the required level, while being in compliance with the regulations, and market demand.