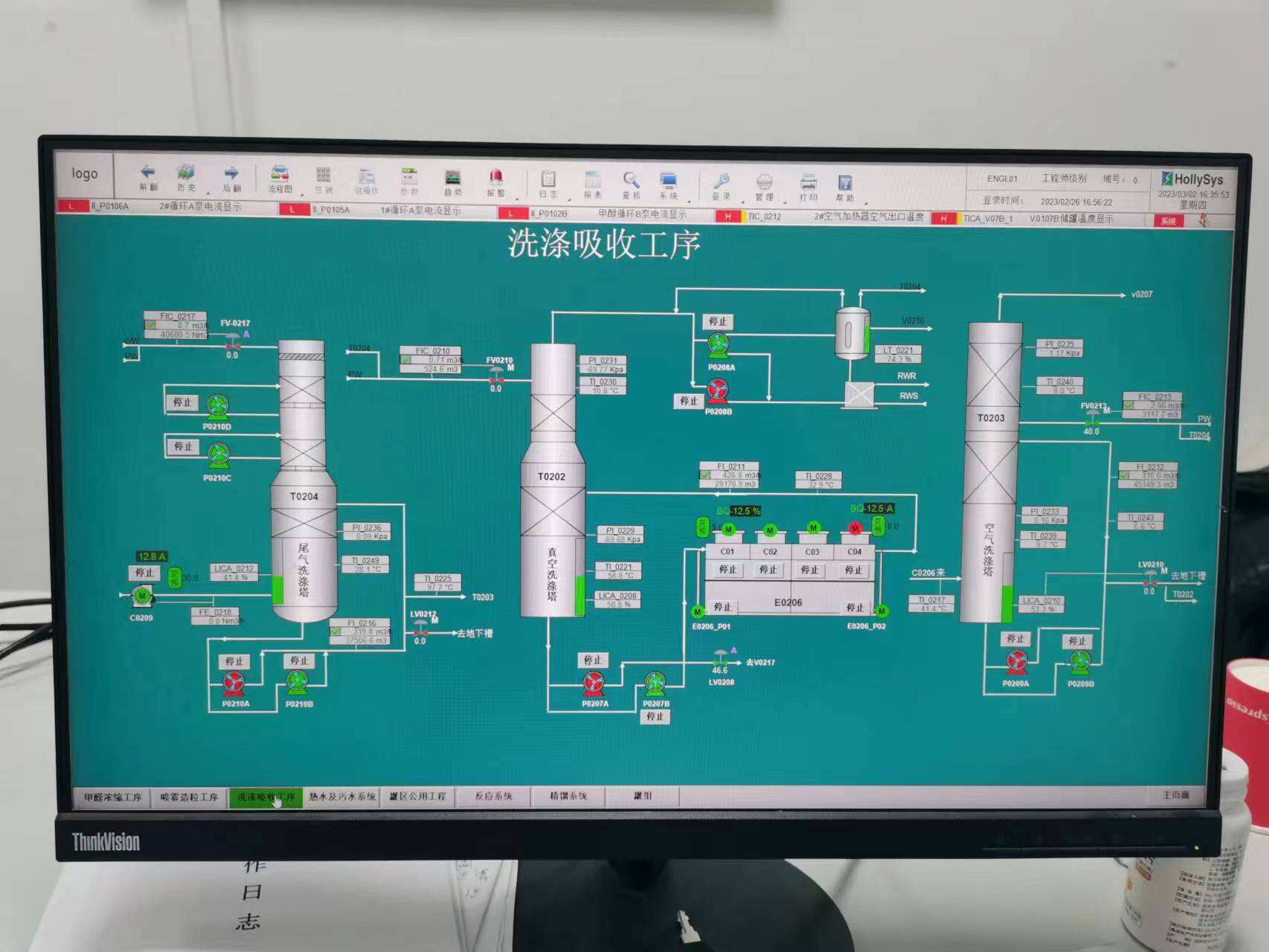

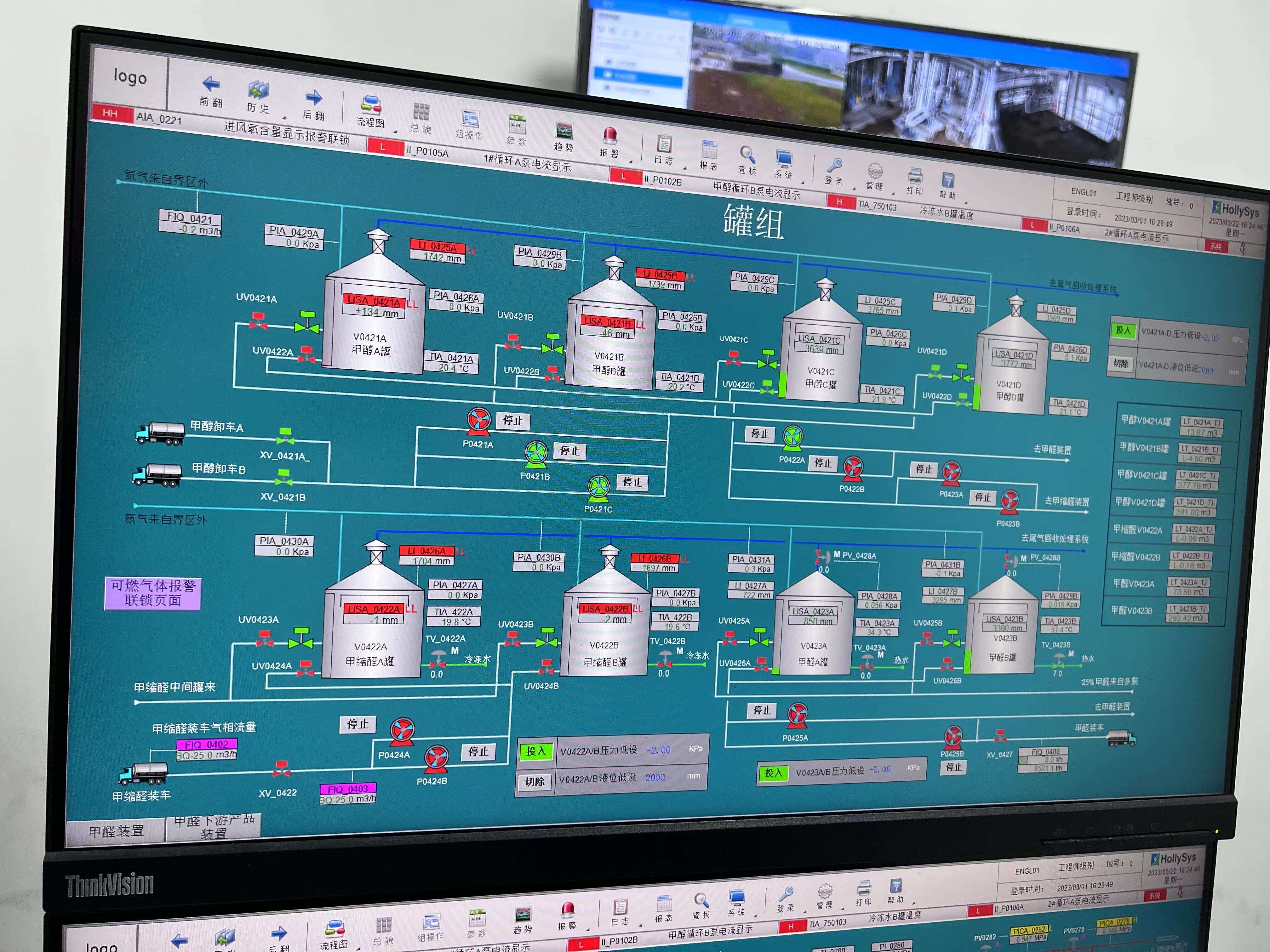

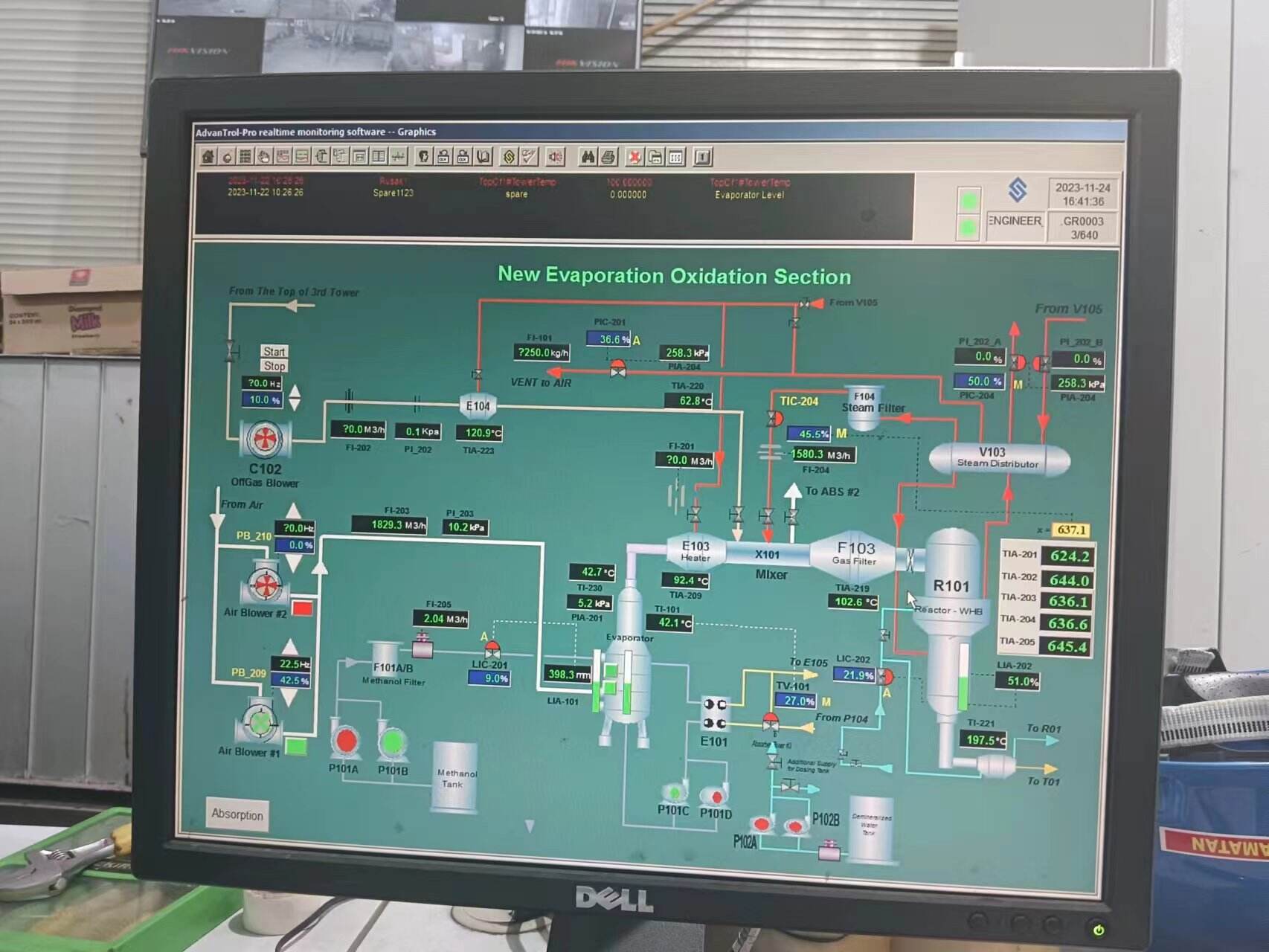

We at Sanli Tech offer industry’s intelligent chemical engineering solution services, allowing it to improve its operational performance. This means that within our abilities falls a range of solutions, such as process components, complete process plants, and technology transfer. We emphasize our capacity to provide services in a broad variety of industrial settings and cultures. Our focus on quality, together with our commitment to innovation, gives us a competitive edge in the chemical engineering industry, providing the clients with a wider latitude of business opportunities for consistent growth.