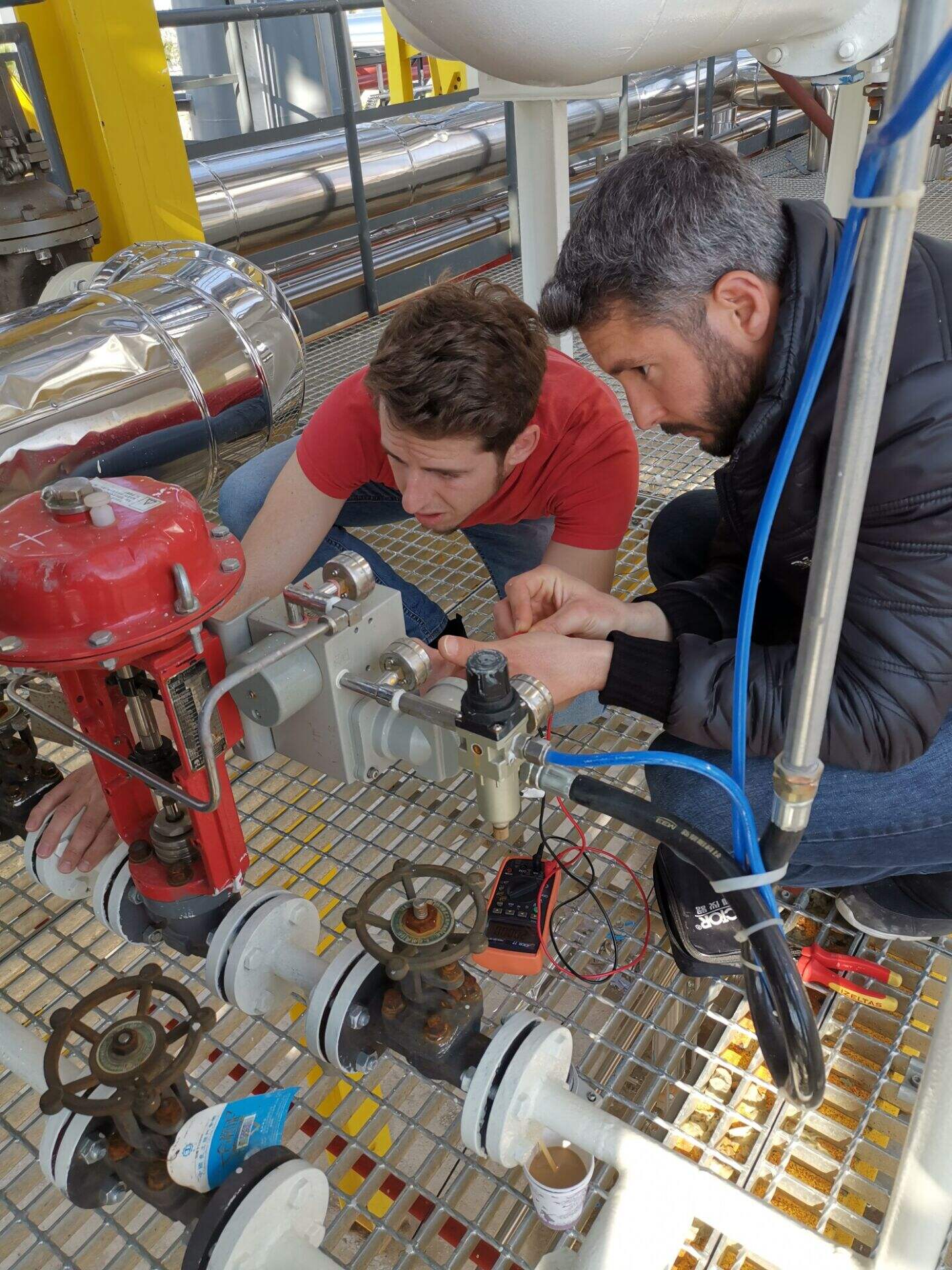

Our onsite consultation is a key element needed for chemical plants to operate smoothly. We place a lot of emphasis on conducting thorough evaluations and safety checks while developing methods for system improvement, Our team will collaborate with your employees to address problems and come up with viable solutions. With the application of advanced chemical engineering techniques, you will be able to improve work, minimize environmental loss and meet legal and administrative requirements. It is the combination of quality and innovations that makes us a reliable ally in this industry.