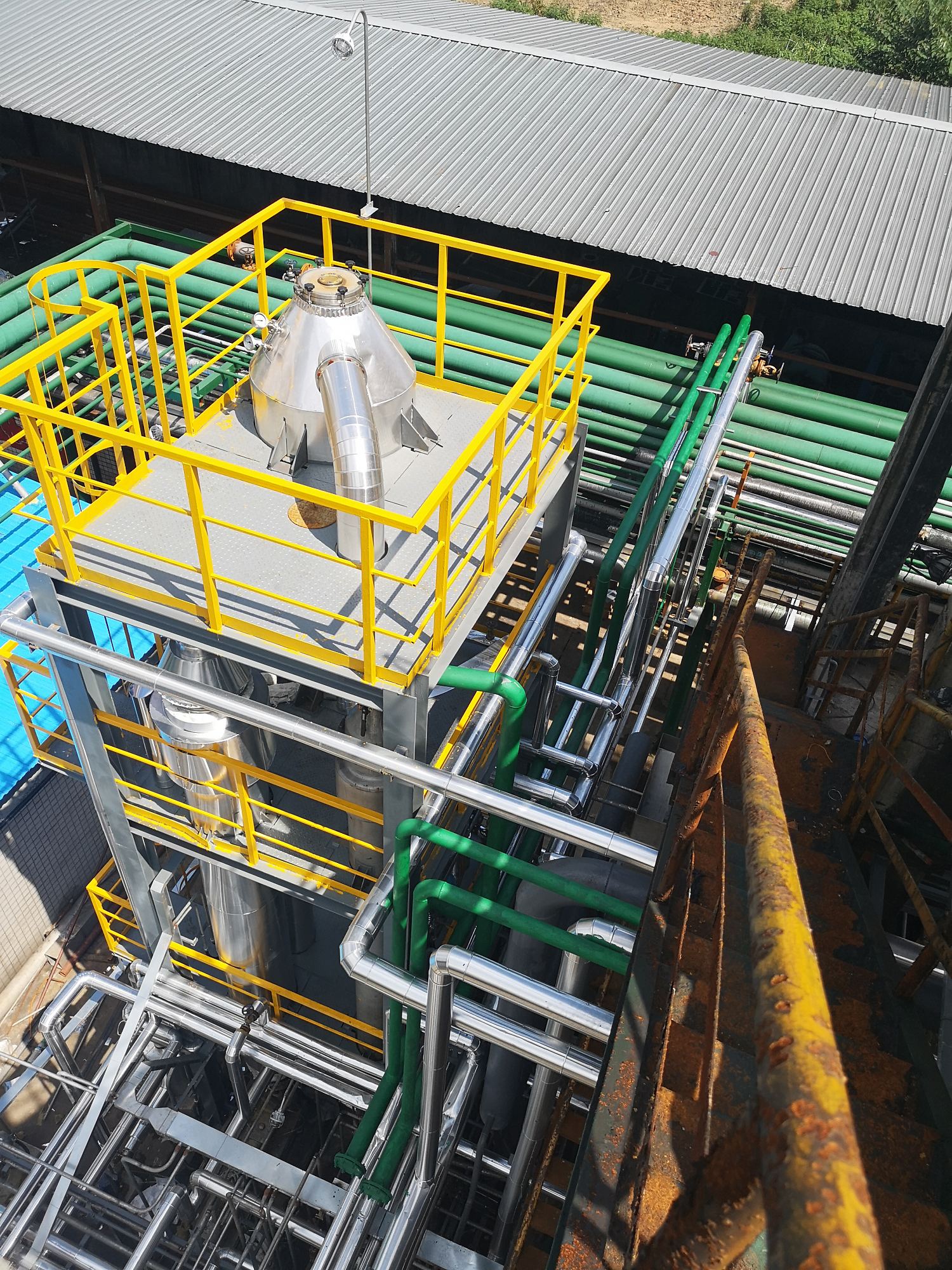

We at Sanli Tech are best known for our modern chemical production tools that enable businesses streamline their processes. Particularly, our systems include chemical engineering technologies that make production more efficient and cost-effective as well as improve the quality of the end-product. Using advanced facilities and deep expertise, we provide the clients with the ability to deal with the intricacies of chemical production, ensuring the highest standards of safety and the most stringent environmental regulations. This innovative approach allows our clients to stay relevant in fast-changing markets.