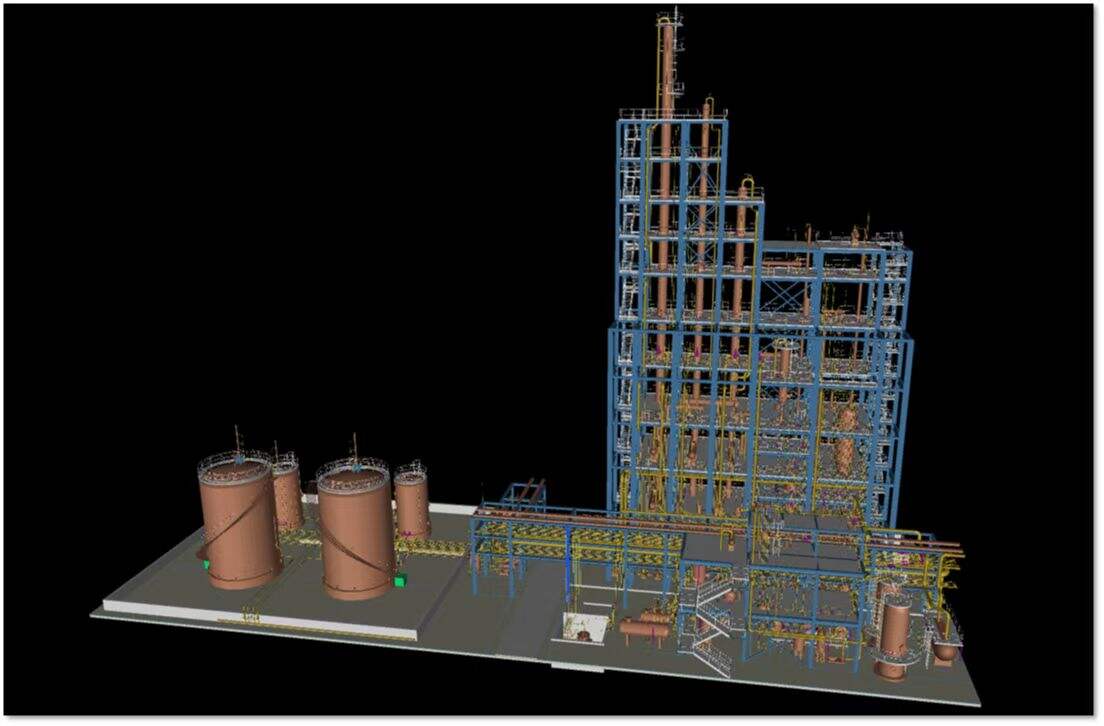

The company’s industrial chemical process design services combine technical expertise with digital innovation, delivering optimized solutions from concept to commissioning. Front-end engineering design (FEED) projects begin with thorough feasibility studies, evaluating process routes using economic metrics like net present value (NPV) and internal rate of return (IRR). For example, a 50 kt/year adipic acid plant design incorporated a novel electrooxidation process, reducing energy consumption by 25% and CO₂ emissions by 40% compared to conventional nitric acid oxidation. Process design packages include P&ID development, equipment sizing (using HTRI for heat exchangers, Chemstations for columns), and safety integrity level (SIL) assessments. Digital twins of the process are created using Emerson DeltaV software, allowing clients to simulate operational scenarios and optimize control strategies before physical implementation.